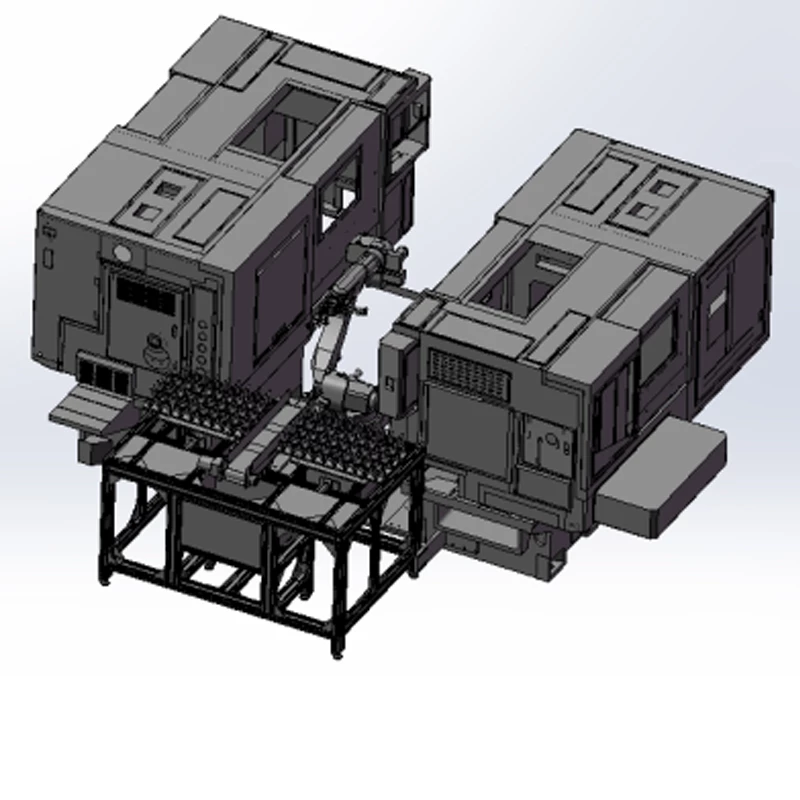

CNC lathe and six joint robotic arm for loading and unloading

|

Six-axis robot parameters |

||||

|

scope of application |

Any form of work piece self-located by artifact shape features. |

|||

|

The dressing run-out |

10 Seconds |

Single piece total run-out |

Product cutting time + 10 seconds |

|

|

Storage drive mode |

Standard cylinder drive |

location mode |

Secondary positioning device positioning |

|

|

Workpiece positioning accuracy |

±0.03 |

Control system |

Domestic/Wistron/Import/ Hust |

|

|

Workpiece tray |

Material: aluminum plate, specification: 660 * 340 * 15, quantity: 2 pieces |

|||

|

Product replacement needs to change the part |

Panel and paw |

|||

|

Characteristic |

Six-axis robot + CNC lathe + dot matrix bin, adapt to the product needs to have a certain batch, can one sequence two sequence automatic turn wire processing. |

|||

|

Electrical conditions are required |

Power supply: 3-phase four-wire 380V; voltage fluctuation range: ± 10%; frequency: 50 HZ; Gas source is required: 0.6 Mpa. |

|||

|

On-site environmental requirements |

Ambient temperature: -10~50°C; relative humidity: 20%~75%; vibration: vibration acceleration <0.5g; electrical cabinet must be grounded, grounding resistance<1; no corrosive gases at the work site; workshop foundation: conventional cement floor treatment. |

|||

Previous: 12-station palletizing truss manipulator