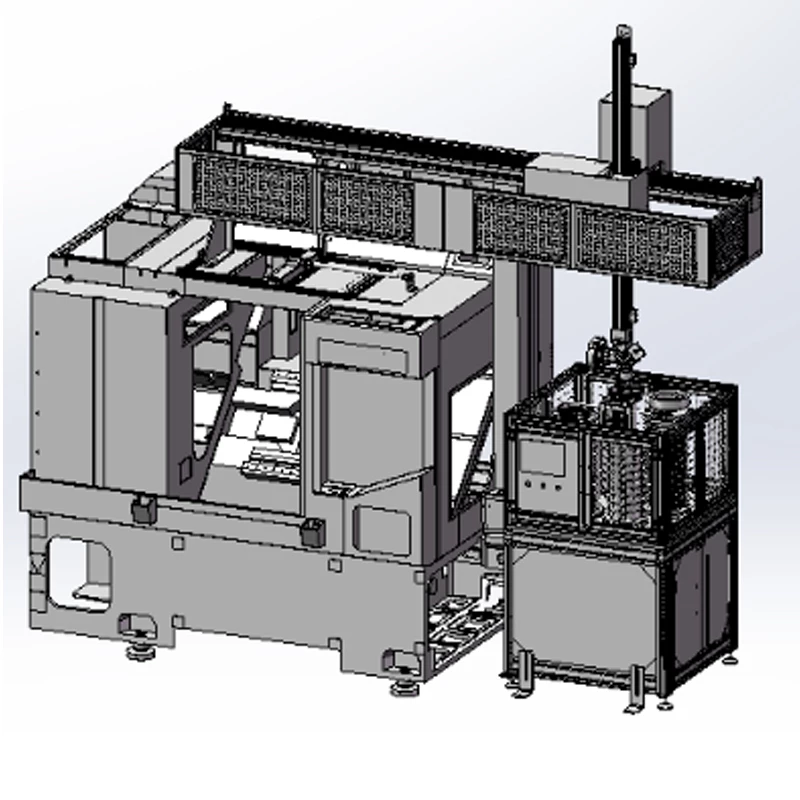

6-station palletizing truss manipulator

|

6 basic parameters of the station palletizing truss manipulator |

||||

|

Scope of application |

Any form of work piece self-located by artifact shape features. |

|||

|

Reloading run-out |

6 seconds (wire harness 3m / s) |

Single piece total run-out |

Product cutting time + 6 seconds |

|

|

Storage drive mode |

Servo motor drive |

location mode |

Secondary positioning device |

|

|

Workpiece positioning accuracy |

±0.03 |

Control system |

Domestic/Wistron/Import/ HUST |

|

|

Charging tray |

Chain, positioning plate, fluent bar, ball ball |

|||

|

Pstemuct replacement needs to change the part |

Positioning disc and paw |

|||

|

Characteristic |

The mobility is very strong. Integration of manipulator and CNC lathe makes it adapt to the new machine and can be flexible processing after relocation and displacement. |

|||

|

Required electrical conditions |

Power supply: 3-phase four-wire 380V; voltage fluctuation range: ± 10%; frequency: 50 HZ; gas source is required: 0.6 Mpa. |

|||

|

On-site environmental requirements |

Ambient temperature: -10~50°C; relative humidity: 20%~75%; vibration: vibration acceleration <0.5g; electrical cabinet must be grounded, grounding resistance<1; no corrosive gases at the work site; workshop foundation: conventional cement floor treatment. |

|||

Previous: One for two truss manipulators